Product Description

Casting and Forging Steel Helical Spiral Custom Planetary Spur CZPT Transmission Timing Gear

| Material | Stainless steel, steel, iron, aluminum, gray pig iron, nodular cast iron malleable cast iron, brass, aluminium alloy |

| Process | Sand casting, die casting, investment casting, precision casting, gravity casting, lost wax casting, ect |

| Weight | Maximum 300 tons |

| Standard | According to customers’ requirements |

| Surface Roughness | Up to Ra1.6 ~ Ra6.3 |

| Heat Treatment | Anneal, quenching, normalizing, carburizing, polishing, plating, painting |

| Test report | Dimension, chemical composition, UT, MT, Mechanical Property, according to class rules |

| Port of loading | HangZhou or as customer’s required |

1.How can I get the quotation?

Please give us your drawing,quantity,weight and material of the product.

2.If you don’t have the drawing,can you make drawing for me? Yes,we are able to make the drawing of your sample duplicate

the sample.

3.When can I get the sample and your main order time? Sample time: 35-40 days after start to make mold. Order time: 35-40 days,

the accurate time depends on product.

4.What is your payment method? Tooling:100% T/T advanced Order time:50% deposit,50%to be paid before shipment.

5.Which kind of file format you can read? PDF, IGS, DWG, STEP, MAX

6.What is your surface treatment? Including: powder coating, sand blasting, painting, polishing, acid pickling, anodizing, enamel, zinc plating, hot-dip galvanizing, chrome plating.

7.What is your way of packing? Normally we pack goods according to customers’ requirements.

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Cast Steel |

| Customization: |

Available

| Customized Request |

|---|

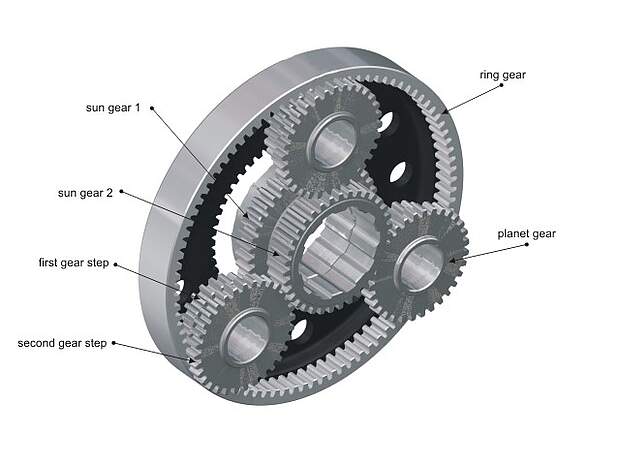

Can planetary gears be used in automotive applications?

Planetary gears are widely used in various automotive applications due to their numerous advantages. Let’s explore how planetary gears can be utilized in the automotive industry:

- Automatic Transmissions:

One of the primary applications of planetary gears in automobiles is in automatic transmissions. Automatic transmissions use a combination of planetary gear sets to achieve different gear ratios, allowing for smooth and efficient shifting between gears. The compact size and high torque capacity of planetary gears make them well-suited for this purpose, providing reliable and efficient power transmission in vehicles.

- Four-Wheel Drive Systems:

Planetary gears are also employed in four-wheel drive systems, where they help distribute power between the front and rear wheels. By utilizing planetary gear arrangements, the torque can be split between the front and rear axles, providing improved traction and stability on various road conditions. This allows vehicles to have enhanced off-road capabilities and better performance in challenging driving situations.

- Hybrid and Electric Vehicles:

Planetary gears play a crucial role in hybrid and electric vehicle powertrains. In these vehicles, planetary gear sets are often used to combine the power from the internal combustion engine and the electric motor. The gear arrangement allows for seamless transitions between different power sources, enabling efficient energy management and optimized performance.

- Start-Stop Systems:

Start-stop systems, which automatically shut off the engine when the vehicle is stationary and restart it when needed, often incorporate planetary gears. These gears help engage and disengage the engine from the drivetrain smoothly, ensuring a quick and seamless transition between the engine’s off and on states. Planetary gears contribute to the overall efficiency and reliability of start-stop systems.

- Power Steering:

Some power steering systems in automobiles utilize planetary gears to provide assistance in steering. These gears help amplify the driver’s input torque, making steering easier and more responsive. The compact size and high torque capacity of planetary gears make them suitable for power steering applications.

In summary, planetary gears find extensive use in automotive applications, including automatic transmissions, four-wheel drive systems, hybrid and electric vehicle powertrains, start-stop systems, and power steering. Their compact size, high torque capacity, and ability to achieve multiple gear ratios make them well-suited for these applications, providing efficient power transmission, improved performance, and enhanced driving experience in vehicles.

What are the considerations for lubrication and maintenance of planetary gears?

Proper lubrication and maintenance are crucial for the reliable and efficient operation of planetary gears. Let’s explore the key considerations for lubrication and maintenance:

- Lubrication:

Effective lubrication is essential to reduce friction, wear, and heat generation in planetary gears. Consider the following aspects:

- Lubricant Selection:

Choose a lubricant specifically designed for gear systems with the appropriate viscosity and additives to ensure proper film formation and protection against wear. Consult the manufacturer’s recommendations or industry standards for suitable lubricants.

- Lubricant Contamination:

Prevent contamination of the lubricant by keeping the gear system clean and free from debris, dust, and moisture. Use proper sealing techniques and consider filtration systems to maintain the lubricant’s cleanliness and performance.

- Lubrication Frequency:

Follow the recommended lubrication intervals provided by the equipment manufacturer. Factors such as operating conditions, load, and temperature can affect the lubrication frequency. Regularly monitor the lubricant condition and conduct oil analysis to determine if lubricant replacement or additional lubrication is required.

- Maintenance:

Regular maintenance helps ensure the longevity and optimal performance of planetary gears. Consider the following maintenance aspects:

- Inspection:

Periodically inspect the gear system for signs of wear, damage, misalignment, or abnormal noise. Detecting issues at an early stage allows for timely maintenance and prevents further damage.

- Alignment:

Proper alignment of the gear components is crucial to distribute the load evenly and prevent premature wear. Regularly check and adjust the gear alignment as per the manufacturer’s specifications.

- Torque and Load:

Ensure that the gear system operates within the recommended torque and load limits. Excessive loads can lead to increased wear and decreased gear life. Consider the application requirements and ensure the gear system is appropriately sized and rated.

- Temperature:

Monitor the operating temperature of the gear system. Excessive heat can degrade the lubricant’s performance and accelerate wear. Proper cooling mechanisms, such as fans or heat exchangers, may be required in high-temperature environments.

In summary, proper lubrication and maintenance are essential for planetary gears. Choose suitable lubricants, prevent contamination, follow recommended lubrication intervals, inspect for wear, ensure proper alignment, consider torque and load limits, monitor operating temperature, and conduct regular maintenance. By adhering to these considerations, you can prolong the lifespan, enhance performance, and minimize the risk of gear failure in planetary gear systems.

How do planetary gears contribute to power transmission and gear reduction?

Planetary gears play a significant role in power transmission and gear reduction. Let’s explore how planetary gears contribute to these aspects:

- Torque Amplification:

One of the key contributions of planetary gears is torque amplification. The arrangement of multiple gear sets in a compact design allows for torque multiplication. When the input power is applied to the sun gear, it drives the rotation of the planet gears. The planet gears, in turn, mesh with the ring gear, creating a mechanical advantage that amplifies the torque output. This torque amplification is beneficial in applications where high torque is required while maintaining a smaller form factor.

- Gear Ratio Variation:

Another contribution of planetary gears is their ability to achieve different gear ratios. By varying the number of teeth on the sun gear, planet gears, and ring gear, a wide range of gear ratios can be obtained. The gear ratio is determined by the relative sizes of the gears and the number of teeth on each gear. This flexibility in gear ratios allows machinery to adapt to varying speed and torque requirements, enabling precise control and efficient power transmission.

- Gear Reduction:

Planetary gears are commonly used for gear reduction applications. Gear reduction refers to the process of reducing the rotational speed and increasing the torque output of a power source. In a planetary gear system, gear reduction is achieved by fixing the ring gear and allowing the sun gear to rotate as the input. The rotation of the sun gear drives the planet gears, which in turn rotate the output carrier or arm. The output speed is slower than the input speed, resulting in gear reduction. This gear reduction capability is valuable in various applications, such as automotive transmissions and power transmission systems.

- Efficient Power Transmission:

Planetary gears are known for their efficient power transmission capabilities. The internal gear meshing and the distribution of load across multiple gear teeth result in efficient torque transfer with minimal power loss. The load is shared among the planet gears, allowing for higher torque capacity and reduced wear on individual gear teeth. This efficient power transmission ensures that a significant portion of the input power is effectively transmitted to the output, making planetary gears suitable for applications where energy conservation and optimization are crucial.

In summary, planetary gears contribute to power transmission and gear reduction through torque amplification, gear ratio variation, gear reduction mechanism, and efficient power transmission. The ability to amplify torque, achieve different gear ratios, and transmit power efficiently makes planetary gears widely used in various industries and mechanical systems.

editor by CX 2023-09-12