Product Description

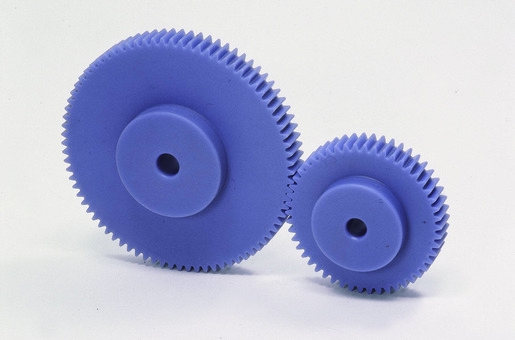

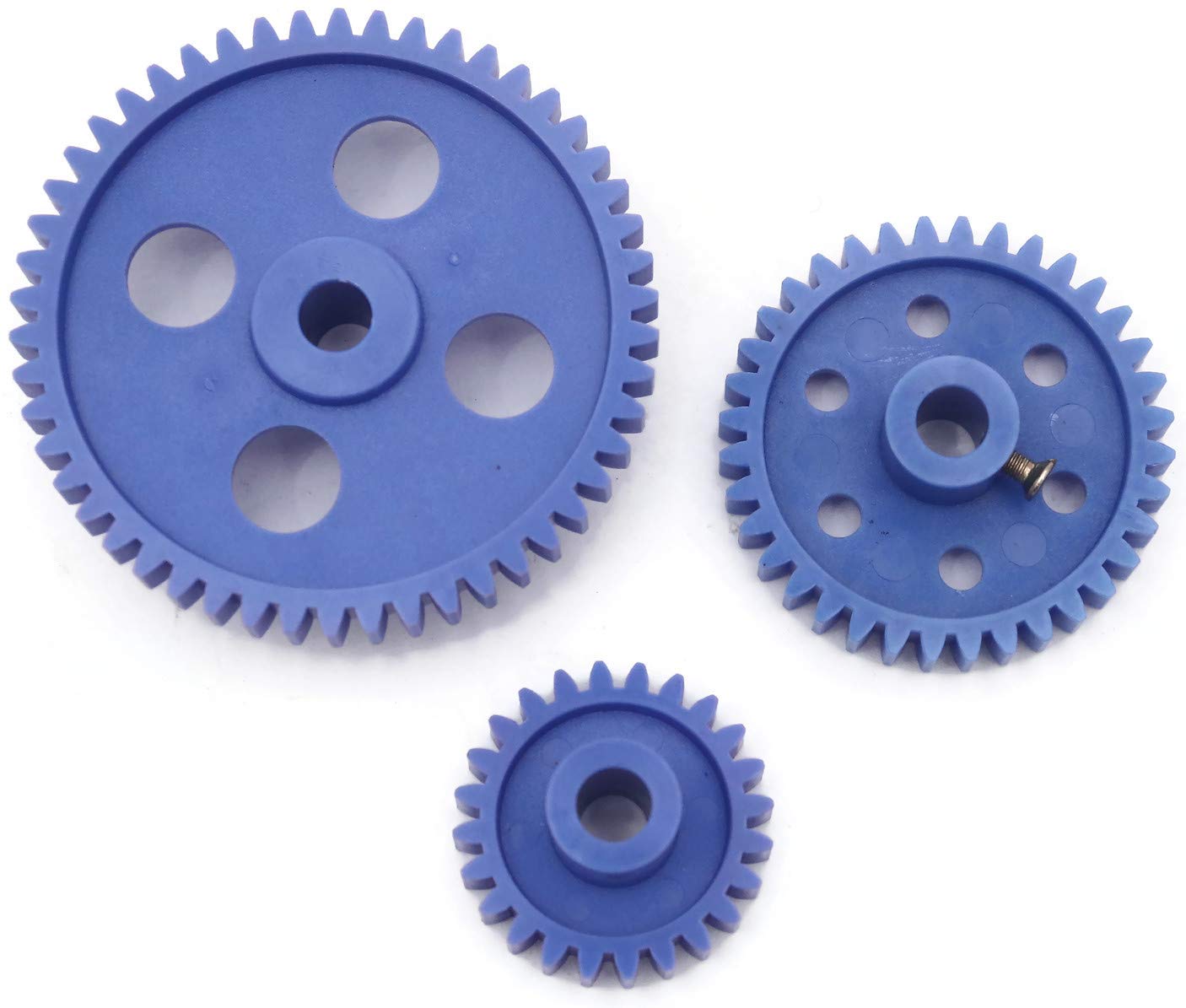

Gear Shaft Wheel Set Pinion Duplex Ground Plastic Nylon Good Price Ground Helical Micro Best Manufacturers Brass Stainless Steel 23 Worm Gears Wheel

Application of Gear Shaft Wheel Set

Gear shaft wheel sets are used in a wide variety of applications, including:

- Machine tools: Gear shaft wheel sets are used in machine tools, such as lathes and milling machines, to transmit power from the motor to the cutting tool.

- Conveyor belts: Gear shaft wheel sets are used in conveyor belts to transmit power from the motor to the belt.

- Elevators: Gear shaft wheel sets are used in elevators to transmit power from the motor to the elevator car.

- Cranes: Gear shaft wheel sets are used in cranes to transmit power from the motor to the crane hook.

- Wind turbines: Gear shaft wheel sets are used in wind turbines to transmit power from the rotor to the generator.

Gear shaft wheel sets are available in a variety of sizes and materials, depending on the application. The size of the gear shaft wheel set will depend on the amount of power that needs to be transmitted. The material of the gear shaft wheel set will depend on the environment in which it will be used.

Here are some of the advantages of using gear shaft wheel sets:

- High efficiency: Gear shaft wheel sets are highly efficient, which means that they can transmit power with minimal loss.

- Long life: Gear shaft wheel sets are designed to last for many years, even under harsh conditions.

- Low maintenance: Gear shaft wheel sets require very little maintenance, which can save you money in the long run.

Overall, gear shaft wheel sets are a versatile and reliable way to transmit power. They are used in a wide variety of applications, and they offer a number of advantages over other types of power transmission systems.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Plastic |

| Toothed Portion Shape: | Worm Gear |

| Material: | Stainless Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

How do you prevent premature wear and degradation in plastic gears?

Preventing premature wear and degradation in plastic gears requires implementing various measures and considerations. Here’s a detailed explanation of how to achieve this:

1. Material Selection: Choose a plastic material with suitable properties for the specific application. Consider factors such as strength, stiffness, wear resistance, and compatibility with operating conditions. Opt for materials that have good resistance to wear, fatigue, and environmental factors to minimize premature degradation.

2. Gear Design: Pay attention to the design of the plastic gears to minimize wear and degradation. Optimize the tooth profile, gear geometry, and load distribution to reduce stress concentrations and ensure even load sharing among the teeth. Incorporate features such as fillets, reinforcements, and optimized tooth profiles to enhance the gear’s durability.

3. Lubrication: Proper lubrication is essential to reduce friction, minimize wear, and prevent premature degradation. Choose lubricants that are compatible with the plastic material and the operating conditions. Ensure adequate lubrication by following manufacturer recommendations and implementing proper lubrication techniques such as oil bath, grease, or dry lubrication.

4. Operating Conditions: Consider the operating conditions and make adjustments to prevent premature wear and degradation. Control operating temperatures within the recommended range for the plastic material to avoid thermal degradation. Avoid excessive speeds or loads that can lead to increased friction and wear. Minimize exposure to harsh chemicals, UV radiation, or abrasive particles that can degrade the plastic material.

5. Maintenance: Implement regular maintenance practices to prevent premature wear and degradation. Conduct periodic inspections to identify signs of wear or damage. Replace worn or damaged gears promptly to prevent further degradation. Follow recommended maintenance schedules for lubrication, cleaning, and any other specific requirements for the plastic gears.

6. Proper Installation: Ensure that plastic gears are installed correctly to minimize wear and degradation. Follow manufacturer guidelines and recommendations for installation procedures, such as proper alignment, torque values, and fastening techniques. Improper installation can lead to misalignment, increased stress concentrations, and accelerated wear.

7. Optimized Load Distribution: Design the gear system to ensure even load distribution across the gear teeth. Consider factors such as tooth profile, tooth width, and the number of teeth to optimize load sharing. Uneven load distribution can lead to localized wear and premature degradation of specific gear teeth.

8. Environmental Protection: Protect plastic gears from harsh environmental conditions that can accelerate wear and degradation. Implement measures such as sealing mechanisms, coatings, or encapsulation to shield the gears from exposure to chemicals, moisture, UV radiation, or abrasive particles.

9. Quality Manufacturing: Ensure high-quality manufacturing processes to minimize defects and inconsistencies that can compromise the durability of plastic gears. Use reputable suppliers and manufacturers that adhere to strict quality control measures. Conduct thorough inspections and testing to verify the quality of the gears before installation.

By considering these preventive measures, such as material selection, gear design, lubrication, operating conditions, maintenance, proper installation, load distribution optimization, environmental protection, and quality manufacturing, it’s possible to minimize premature wear and degradation in plastic gears, ensuring their longevity and performance.

What are the advantages of using plastic gears in machinery?

Plastic gears offer several advantages when used in machinery. Here’s a detailed explanation of the advantages of using plastic gears:

- Lightweight: Plastic gears are significantly lighter in weight compared to metal gears. This lightweight characteristic is particularly beneficial in applications where weight reduction is important, as it can contribute to energy efficiency, lower inertia, and reduced wear on supporting components.

- Low Noise and Vibration: Plastic gears have inherent damping properties, which help reduce noise and vibration levels during operation. The ability to absorb and dissipate vibrations leads to quieter machinery, making plastic gears suitable for applications where noise reduction is desired, such as in consumer electronics or office equipment.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals. This makes plastic gears suitable for applications in corrosive environments, where metal gears may suffer from degradation or require additional protective coatings.

- Self-Lubrication: Some plastic materials used for gear manufacturing have self-lubricating properties. These materials can reduce friction and wear between gear teeth, eliminating the need for external lubrication. Self-lubricating plastic gears can simplify maintenance requirements and reduce the risk of lubricant contamination or leakage in machinery.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production. Plastic materials are often less expensive than metals, and the manufacturing processes for plastic gears can be more efficient, resulting in lower overall production costs. This cost advantage makes plastic gears an attractive option for applications where budget considerations are important.

- Design Flexibility: Plastic gears offer greater design flexibility compared to metal gears. Plastic materials can be easily molded into complex shapes, allowing for the creation of custom gear profiles and tooth geometries. This design flexibility enables gear optimization for specific applications, improving performance, efficiency, and overall machinery design.

- Electrical Insulation: Plastic gears provide electrical insulation properties, which can be advantageous in machinery where electrical or electronic components are in close proximity to the gears. The electrical insulation helps prevent the risk of electrical short circuits or interference caused by metal gears coming into contact with conductive parts.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the machinery and the mechanical properties of the chosen plastic material.

editor by CX 2023-10-16