Product Description

Product Description

| 1.Specialization in CNC formulations of high precision and quality product-list-1.html |

| 2.Independent quality control department |

| 3.Control plan and process flow sheet for each batch |

| 4.Quality control in all whole production |

| 5.Meeting demands even for very small quantities or single units |

| 6.Short delivery times |

| 7.Online orders and production progress monitoring |

| 8.40 years of bearing experience, mature technology, and a number of inventions and utility model patents. |

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

ZheJiang Province Tonging Auto Synchronizer Co., Ltd and ZheJiang Shshi Xihu (West Lake) Dis.g Gears Co. Ltd are focus on the production of space parts for the CHINAMFG over 35years. a professional company in the field.

Our spare parts are interchangeable with the major manufacturers of heavy duty trucks, buses, light commercial and 4×4 pick up vehicles, medium and heavy duty Japanese applications. New items developing for customized in earthmover and agriculture machines.

There are 1 forging production line of 1600 tons, several forging production lines from 400 tons to 1000 tons: more than 300 various manufacturing and inspecting equipments with high efficiency and precision; 2 heat treatment production lines.

Our company can achieve more production process of forging, hobbing, shaving, gear

shaping, grinding and heat treatment.

There are 4 factories affiliated to the company, including Gear Factory, Synchronizer Factory, Adjusting Arm Factory and Casting Factory, producing various Transmission Synchronizers;

Differential Gears; Cross Spiders; Differential cases and other parts. We produce those parts for various types of

domestic trucks, Japanese trucks, European trucks and other famous brands. Moreover, the Agriculture machinery gears and Engineering machinery gears can developing also.

As a member of China Gear Industry Association and China

Auto Gear Manufacture Association, our company always focuses

on technology and quality. The company is an AAA enterprise, got lATF16949:2016 Quality Management System Certificate and has been awarded as Honest and Faithful Company several times by

government. Our products occupy large share of China and we established cooperation relations with CHINAMFG Group. Meanwhile, our products become very popular in Southeast Asia, Europe. Middle

East, Russia, America and other foreign countries.

With superior quality and excellent service, we are ready to offer

our products and service to costumers of all over the world!

Material: 20CrMnTiH

Scope and Capability of Gear Processing:

Modulus 1 to 10

Grade 6 of grinding accuracy

Grade 8 of accuracy achieved by shaving

Maximum machining diameter 400mm

Heat treatment: Quenching and tempering +carburizing

Gearboxes

Input shafts

Gears

Sliding sleeves

Hubs and synchronizer cones

Planet carriers

Housing

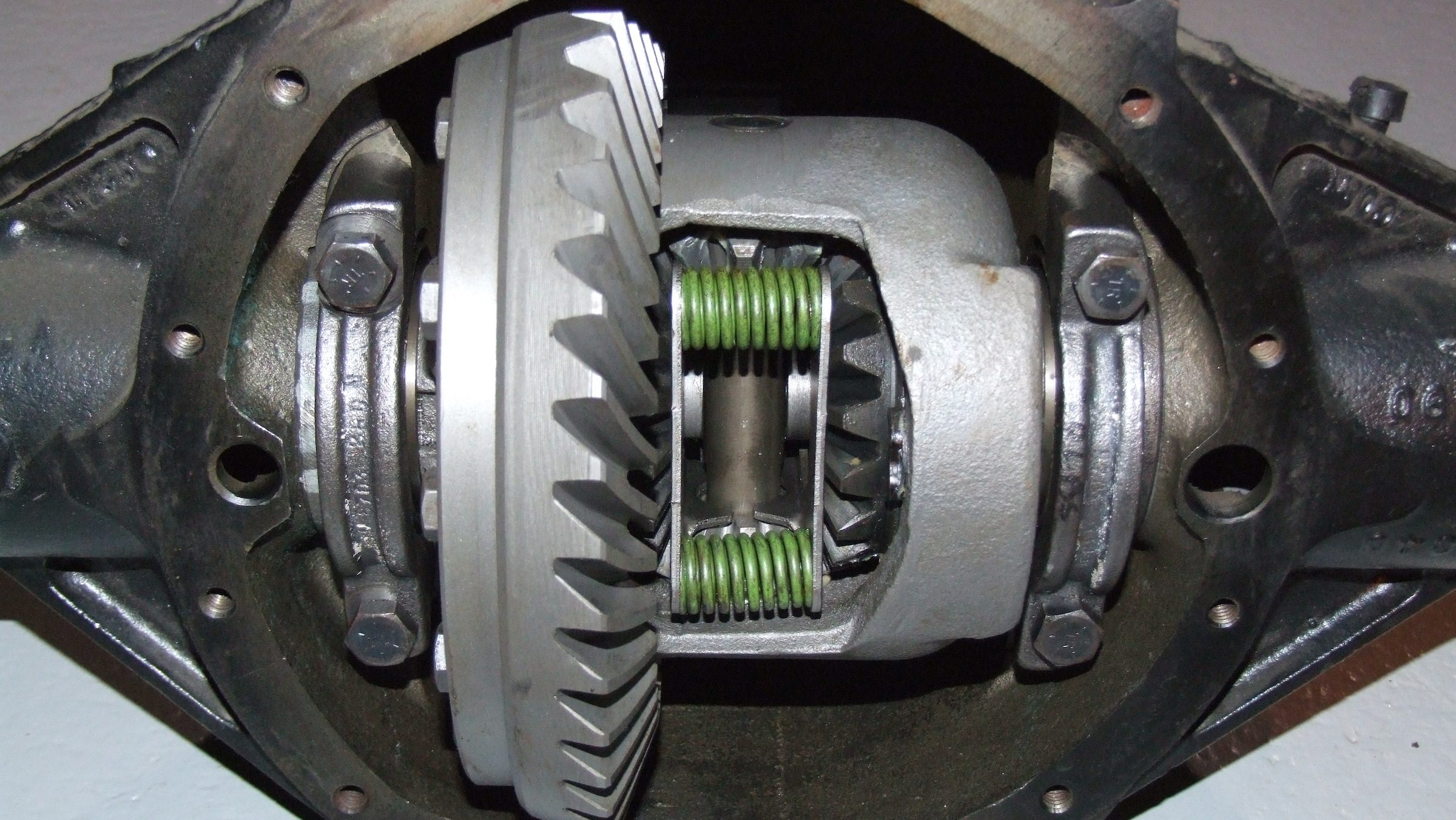

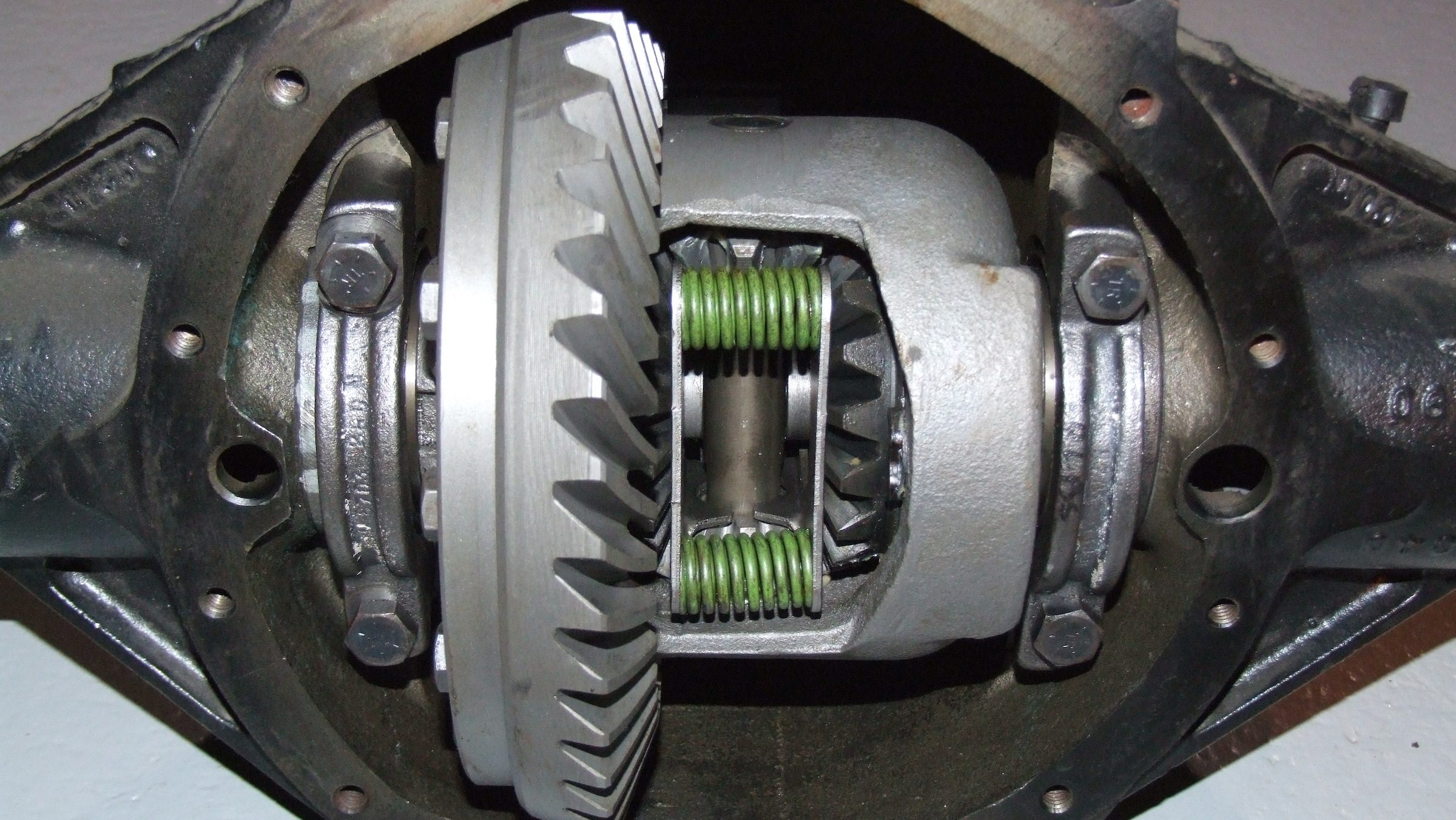

Differentials

Loaded differential cases

Idler pinions and side gears

Gears

Differential kits

Differential Input Shafts

FAQ

| Q1. What is your terms of packing? |

| A: Generally, we pack our goods in Crates/Pallet/Boxes/Cartons. |

| Q2. How about your delivery time? |

| A: Generally, it is 3-7days if the goods are in stock,or it is need 20-30days to producing, |

| it is according to the quantity. |

| Q3. Can you produce according to the samples? |

| A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures. |

| Q4. Do you test all your goods before delivery? |

| A: Yes, we have 100% test before delivery |

| Q5.Do you provide samples?is it free or extra? |

| A:yes,we could offer the sample for free,but do not pay the cost of freight. |

| Q6.What is your term of payment |

| A:payment less than 3000usd,100% in advance,payment more than 6000usd,30%payment before produce,70% balance payment before shipment. |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 1 |

| Type: | Engine Bearing |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

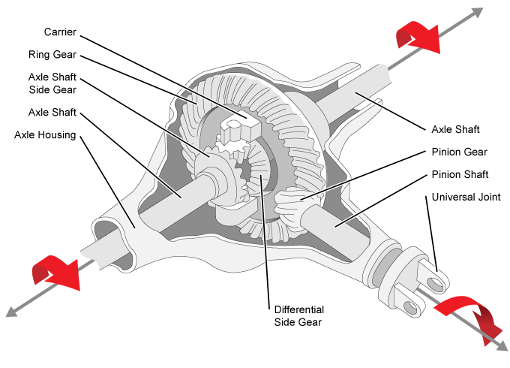

What are the symptoms of a failing differential gear?

A failing or faulty differential gear can exhibit various symptoms that indicate potential problems with its operation. Here are some common signs to look out for:

- 1. Whining or Howling Noises: A prominent symptom of a failing differential gear is the presence of whining, howling, or rumbling noises coming from the rear of the vehicle. These noises may increase with vehicle speed or during specific driving maneuvers, such as turning or accelerating. The noises can indicate worn or damaged gears, insufficient lubrication, or misalignment within the differential assembly.

- 2. Clunking or Clicking Sounds: Another symptom of a failing differential gear is the occurrence of clunking or clicking sounds, particularly during changes in direction or when shifting between drive modes. This can indicate worn or damaged gears, worn universal joints, or loose components within the differential.

- 3. Vibration or Shuddering: A failing differential gear may cause vibration or shuddering sensations, especially when accelerating or decelerating. This can be a result of worn or damaged gears, improper gear meshing, or worn bearings within the differential assembly.

- 4. Difficulty in Turning: If the differential gear is experiencing issues, you may notice increased difficulty in turning the vehicle, particularly during sharp turns or low-speed maneuvers. This can be caused by uneven torque distribution or limited mobility of the differential gears.

- 5. Fluid Leaks: Leaking fluid around the differential housing is a potential indicator of a failing gear. Differential fluid is essential for lubrication and cooling of the gears and bearings. A leak can result from worn seals, cracked housing, or damaged components within the differential assembly.

- 6. Excessive Tire Wear: A failing differential gear may lead to uneven tire wear. If you notice significant wear on the inner or outer edges of the tires, it could be a sign of differential problems. Uneven torque distribution can cause increased stress on specific tires, leading to abnormal wear patterns.

- 7. Gear Slippage: In severe cases, a failing differential gear may result in gear slippage. This means that power is not being effectively transferred to the wheels, causing a loss of traction and reduced vehicle performance. Gear slippage can occur due to worn or damaged gears, insufficient lubrication, or other internal failures within the differential.

If you observe any of these symptoms, it is recommended to have your vehicle inspected by a qualified mechanic or technician. They can diagnose the exact cause of the issues and determine if the differential gear requires repair or replacement.

What is the process for diagnosing and repairing a differential gear issue?

Diagnosing and repairing a differential gear issue involves several steps to identify the problem accurately and implement the necessary repairs. Here’s a detailed explanation of the process:

- Initial Inspection: The process begins with a visual inspection of the differential gear assembly and surrounding components. This includes checking for any signs of leaks, damage, or abnormal wear. The technician will also listen for unusual noises, such as grinding, whining, or clunking sounds, which can indicate potential issues.

- Fluid Inspection: The next step is to inspect the differential gear oil. The technician will check the fluid level and condition. Contaminated or low fluid levels can contribute to differential problems. If the fluid appears dirty, metallic, or has a burnt smell, it may indicate internal damage or excessive wear.

- Test Drive: A test drive is often conducted to observe the vehicle’s behavior and confirm the presence of any differential gear issues. The technician will pay attention to abnormal noises, vibrations, or handling characteristics that may point to specific problems within the differential assembly.

- Differential Disassembly: If a differential issue is suspected, the technician may need to disassemble the differential assembly for a more detailed inspection. This involves removing the driveshaft, axles, and other components to gain access to the differential gears. The differential housing and gears are carefully inspected for signs of wear, damage, or misalignment.

- Measurement and Evaluation: Precision measurements are taken to assess the condition of the differential gears, bearings, and related components. This may involve using specialized tools to check gear backlash, gear tooth wear, bearing clearances, and other critical parameters. These measurements help determine the extent of the problem and whether components need to be repaired or replaced.

- Component Repair or Replacement: Based on the evaluation, the technician will determine the appropriate repair or replacement actions. Damaged or worn components such as gears, bearings, seals, or shims may need to be replaced. In some cases, the entire differential assembly may need to be replaced if the damage is extensive or the cost of repairs outweighs replacement.

- Reassembly and Adjustment: Once the necessary repairs or replacements have been made, the differential assembly is reassembled with new components. Proper adjustments are made to ensure correct gear meshing, preload, and backlash. The technician will also refill the differential with the recommended fluid and perform any additional adjustments or calibrations as required.

- Final Testing: After reassembly, a final test drive is conducted to verify that the differential gear issue has been successfully resolved. The technician will listen for abnormal noises, monitor handling characteristics, and assess overall performance to ensure proper functionality of the repaired differential.

In summary, diagnosing and repairing a differential gear issue involves an initial inspection, fluid inspection, test drive, differential disassembly, measurement and evaluation, component repair or replacement, reassembly and adjustment, and final testing. This systematic process helps identify the problem, determine the necessary repairs, and restore the differential gear to proper working condition.

Are there different types of differential gears available?

Yes, there are different types of differential gears available, each designed to suit specific driving conditions and performance requirements. Here’s an overview of some commonly used types of differential gears:

1. Open Differential:

An open differential is the most basic and widely used type of differential gear. It allows the wheels to rotate at different speeds during turns while equally distributing torque. In normal driving conditions, an open differential provides smooth operation and is relatively inexpensive. However, it has limited traction improvement capabilities and may distribute power to the wheel with the least resistance, which can be a disadvantage in low-traction situations.

2. Limited-Slip Differential (LSD):

A limited-slip differential (LSD) improves upon the capabilities of an open differential by providing some degree of torque biasing. LSDs use various mechanisms, such as clutch packs, viscous fluids, or gear arrangements, to transfer more torque to the wheel with better traction. This helps improve traction and power delivery, especially in situations where one wheel has reduced traction. LSDs strike a balance between improved traction and maintaining drivability for everyday use.

3. Electronic Limited-Slip Differential (ELSD):

An electronic limited-slip differential (ELSD) is a modern variation of the limited-slip differential. It incorporates electronic sensors and actuators to actively monitor wheel speeds and traction conditions. The ELSD can quickly and precisely distribute torque to the wheels with better traction, enhancing overall performance and stability. ELSDs are often found in high-performance or advanced all-wheel drive systems.

4. Torsen Differential:

A Torsen (short for Torque-Sensing) differential is a type of differential gear that uses a worm gear arrangement to distribute torque. Torsen differentials can provide a higher torque biasing ratio compared to LSDs. They have a mechanical, self-acting design that automatically transfers torque to the wheel with better traction. Torsen differentials are commonly used in performance-oriented vehicles and off-road applications.

5. Locking Differential:

A locking differential is designed to maximize traction in off-road or extreme driving conditions. It allows both wheels to receive an equal amount of torque simultaneously, regardless of traction conditions. Locking differentials can be manually engaged or automatically activated by sensors detecting wheel slip. While locking differentials enhance traction, they can also negatively impact handling on paved surfaces, making them more suitable for off-road or specialized applications.

6. Torque Vectoring Differential:

A torque vectoring differential is a more advanced type of differential that actively distributes torque to individual wheels to enhance vehicle dynamics. It uses electronic systems to monitor various vehicle parameters, such as wheel speed, steering input, and lateral acceleration. By selectively applying torque to specific wheels, torque vectoring differentials can improve cornering performance, stability, and agility.

These are just a few examples of the different types of differential gears available. Each type offers unique characteristics and advantages, allowing vehicle manufacturers to tailor the differential system to specific driving conditions, performance requirements, and driver preferences.

editor by Dream 2024-05-03