Product Description

Advance HCT1100 marine main propulsion reduction gearbox,; with advance gearbox list as:;

| Model | Max Power Input (hp/rpm); |

Speed Rang (rpm); |

Reduction Ration | Weight | Suitable Engines |

| 06 | 12.;5/2100 | 1000-2100 | 2.;52/3.;05/3.;50 | 58kg | Yanmar TS130/TS155 Hatz E786 |

| 16A | 33/2000 | 1000-2000 | 2.;07/2.;48/2.;95/3.;35/3.;83 | 84kg | MWM D226-2,; Hatz 3M31 |

| MA100A | 37/3000 | 1500-3000 | 1.;6/2/2.;55/3.;11/3.;59/3.;88 | 75 | Isuzu UM02AB1,; CHINAMFG ME125 |

| MA125 | 82/3000 | 1500-3000 | 2.;03/2.;46/3.;04/3.;57/4.;05 /4.;39/4.;7 |

115 | Isuzu UM02AB1,; CHINAMFG ME125 |

| MA142 | 102/2500 | 1500-3000 | 1.;97/2.;52/3.;03/3.;54/3.;95/4.;5 | 140 | Cummins 4BTA3.;9-M MWM D226-4 |

| 40A | 82/2000 | 750-2000 | 2.;07/2.;96/3.;44 | 225 | Yanmar ME400L,; Baudouin 4D |

| MB170 | 132/2500 | 1000-2500 | 1.;97/2.;52/3.;04/3.;96/4.;5/5.;06 /5.;47/5.;88 |

240 | MWM D226-6,; CHINAMFG ME400L |

| HC65 | 163/2500 | 1000-2500 | 1.;53/2.;03/2.;5/2.;96 | 130 | 6BT5.;9-M |

| 120B | 750-1800 | 2.;03/2.;81/3.;73 | 400 | ||

| 120C | 340/2500 | 1000-2500 | 1.;48/1.;94/2.;45/2.;96/3.;35 | 225 | Cummins NT855-M240,; CAT 3208TA |

| MV100 | 408/3000 | 1500-3000 | 1.;23/1.;62/2.;07/2.;52/2.;87 | 220 | NT855-M240,; MWM D234 V8 |

| 135A | 272/2000 | 1000-2000 | 2.;03/2.;59/3.;04/3.;62/4.;11/4.;65 /5.;06/5.;47/5.;81 |

470 | NT855-M240,; CAT 3406 |

| HCQ138 | 390/2600 | 1000-2600 | 1.;03/1.;5/2.;03/2.;48/2.;95 | 200 | NT855-M240,; CAT 3406 |

| HC138 | 375/2500 | 1000-2500 | 2/2.;52/3/3.;57/4.;05/4.;45 | 360 | 6135Ca,; NT855-M240 |

| HCD138 | 375/2500 | 1000-2500 | 5.;05/5.;63/6.;06/6.;47 | 415 | 6135Ca,; NT855-M240 |

| HCA138 | 390/2600 | 1000-2600 | 1.;095/1.;28/1.;5/2.;03/2.;52/3 | 200 | NT855-M240,; MWM D234 V8 |

| MB242 | 350/2500 | 1000-2500 | 3.;04/3.;52/3.;95/4.;53/5.;12 /5.;56/5.;88 |

385 | NT855-M240,; CAT 3406 |

| HC200 | 440/2200 | 1000-2200 | 1.;48/2/2.;28 | 280 | NT855-M240,; CAT 3406TA |

| HC201 | 500/2500 | 1000-2500 | 2.;46/2.;955/3.;526 | 350 | 6135ZLCa,; CHINAMFG NTA855-M400 |

| MB270A | 500/2500 | 1000-2500 | 4.;05/4.;53/5.;12/5.;5/5.;95/6.;39/6.;82 | 675 | NTA855-M400,; CAT 3406TA |

| HCQ300 | 782/2300 | 1000-2300 | 1.;05/1.;46/2.;05/2.;38 | 350 | KTA19-M600,; 3412T,; TBD234 V12 |

| 300 | 805/2300 | 1000-2300 | 2.;04/2.;54/3/3.;53/4.;1/4.;61/4.;94 /5.;44 |

740 | KTA19-M600,; TBD234 V12 |

| D300 | 805/2300 | 1000-2300 | 4/4.;48/5.;05/5.;52/5.;9/6.;56/7.;06 /7.;63 |

940 | KTA19-M600,; TBD234 V12 |

| T300 | 759/2300 | 1000-2300 | 4.;95/6.;03/6.;65/7.;04/7.;54/8.;02 /8.;47 |

1120 | KTA19-M600,; 3412T,; TBD234 V12 |

| T300/1 | 611/2300 | 1000-2300 | 8.;94/9.;45 | 1120 | KTA19-M600,; 3412T |

| HCA300 | 850/2500 | 1000-2500 | 1.;5/2/2.;57/2.;95 | 370 | KTA19-M600,; 3412T,; TBD234 V12 |

| M300 | 850/2300 | 1000-2300 | 1.;45/2/2.;52/3.;05/3.;45/3.;94 | 700 | KTA19-M600,; TBD234 V12 |

| MD300 | 850/2300 | 1000-2300 | 3.;96/4.;48/4.;96/5.;52/5.;9 | 940 | KTA19-M600,; TBD234 V12 |

| HCQ400 | 810/1800 | 1000-2300 | 1.;5/2.;04/2.;5/3/3.;42/3.;77/4.;06 /4.;61/4.;94 |

1100 | KT38-M800,; TBD604BL6,; 3412TA |

| HC400 | 810/1800 | 1000-2300 | 1.;5/2.;04/2.;5/3/3.;42/3.;77/4.;06 /4.;61/4.;94 |

820 | 3412TA,; TBD604BL6 |

| HCD400A | 810/1800 | 1000-1800 | 3.;96/4.;33/4.;43/4.;476/4.;7/5/5.;53 /5.;7/5.;89 |

1100 | KT38-M800,; TBD604BL6 |

| HCT400A | 945/2100 | 1000-2100 | 6.;09/6.;49/6.;93/7.;42/7.;95/8.;4 /9/9.;47 |

1450 | KT38-M800,; 6BD604BL6 |

| HCT400A/1 | 945/2100 | 1000-2100 | 8.;15/8.;69/9.;27/10.;6/11.;46/12 | 1500 | KTA38-M800,; 3412TA,; TBD604BL6 |

| HCQ501 | 1265/2300 | 1000-2300 | 1.;03/1.;46/2/2.;45 | 560 | KTA38-M940,; 3508B,; TBD234 V16 |

| HCQ502 | 1265/2300 | 1000-2300 | 2.;95 | 700 | KTA38-M940,; 3508TA,; TBD234 V16 |

| HC600A | 1365/2100 | 1000-2100 | 2/2.;48/3/3.;58/3.;89 | 1300 | KTA38-M1045,; 3508B,; TBD604B V8 |

| HCD600A | 1365/2100 | 1000-2100 | 4.;18/4.;43/4.;7/5/5.;44/5.;71 | 1550 | KTA38-M1045,; 3508B,; TBD604B V8 |

| HCT600A | 1260/2100 | 1000-2100 | 6.;06/6.;49/6.;97/7.;51/8.;04/8.;66/9.;35 | 1600 | KTA38-M940,; 3508TA,; TBD234 V16 |

| HCT600A/1 | 1260/2100 | 1000-2100 | 7.;69/8.;23/8.;82/9.;47/10.;1/10.;8 /11.;65/12.;57/14.;44 |

1700 | KTA38-M940,; TBD234 V16 |

| HCD800 | 1530/1800 | 1000-1800 | 3.;429/3.;96/4.;391/4.;905/5.;474/5.;889 | 1900 | 6190Z1CZ,; CW6200,; KTA38-M1 |

| HCT800 | 1530/1800 | 800-1800 | 4.;95/5.;57/5.;68/5.;93/6.;43/6.;86 /7.;33/7.;84 |

2000 | KTA38-M |

| HCT800-1 | 800-1800 | 6.;91/7.;28/7.;69/8.;12/8.;6/9.;12 /9.;68/10.;3/10.;98/11.;76/12.;43 /13.;17/13.;97/14.;85/15.;82/16.;58 |

3200 | ||

| HC900 | 1440/1600 | 600-1600 | 1.;46/2.;04/2.;47/3/3.;6/4.;08/4.;63/4.;95 | 1600 | 12V190DC,; M200 |

| HCT1100 | 1841/1600 | 700-1600 | 5.;6/5.;98/6.;39/6.;85/7.;35/7.;9 | 3000 | CW6200 |

| HC1200 | 600-1900 | 2.;03/2.;5/2.;96/3.;55/3.;79/4.;05/4.;2/4.;47 | 2000 | ||

| HC1250 | 1654/1800 | 400-1800 | 2.;03/2.;48/3.;04/3.;48/3.;96 | 2200 | CW8200ZC,; 6210ZL,; Z12V190 |

| HC701 | 1286/2400 | 1200-2400 | 1.;93/2.;58/2.;9/3.;26/3.;91/4.;6/5.;17 /6.;18/7/7.;47 |

2000 | KTA38-M2 |

manufactured by 1 of the biggest gearbox manufacturer in China,; with technologies

introduced from Bosch,; Twindisc,; Eaton,; etc.;

Besides gearbox,; we mainly sell diesel/petrol engines and related spare parts,; with brands

including:; Cummins,; Deutz,; CAT,; ,; Isuzu,; VM,; Toyota,; Mitsubishi,; Suzuki,; Yuchai,;

Weichai,; Changchai,; etc,; for various applications,; such as automobile,; bus,; coach,; van,; truck,;

bulldozer,; forklift,; excavator,; road roller,; wheel loader,; hoister,; generator,; water pump,;

fire pump,; marine main propulsion,; marine auxiliary,; etc.;

| Application: | Marine, Marine |

|---|---|

| Hardness: | Soft Tooth Surface |

| Type: | Worm and Wormwheel |

| Flywheel Housing: | SAE 0#, SAE 00# |

| Material: | Stainless Steel |

| Control: | Pull-Push Flexible Shaft, Electrical, Pneumatical |

Can plastic gears withstand high torque and load conditions?

Plastic gears have certain limitations when it comes to withstanding high torque and load conditions. Here’s a detailed explanation of their capabilities:

Plastic gears can be designed and manufactured to handle a range of torque and load conditions, but their performance is generally inferior to that of metal gears in high-stress applications. The specific capabilities of plastic gears depend on various factors, including the chosen plastic material, gear design, tooth profile, and operating conditions.

While plastic gears may not be suitable for extremely high torque or heavy-load applications, they can still provide reliable performance in many moderate-load scenarios. Plastic gears are commonly used in applications with light to moderate loads, where their unique properties and advantages outweigh their limitations.

Some plastic materials, such as acetal (POM) and polyamide (nylon), offer good strength and wear resistance, allowing them to handle moderate torque and load conditions. These materials can be reinforced with additives or fillers to enhance their mechanical properties and increase their load-bearing capacity.

It’s important to note that when designing with plastic gears, engineers must carefully consider factors such as gear size, tooth geometry, material selection, and operating conditions. Reinforcement techniques, such as using metal inserts or reinforcing fibers, may be employed to improve the strength and load-bearing capabilities of plastic gears in certain applications.

In high torque or heavy-load applications, metal gears, particularly those made from steel or other high-strength alloys, are generally preferred due to their superior strength and durability. Metal gears offer higher load capacities, better resistance to deformation, and increased resistance to wear under extreme conditions.

Ultimately, the suitability of plastic gears for high torque and load conditions depends on the specific requirements of the application and the trade-off between the benefits of plastic gears, such as weight reduction and noise reduction, and the higher load-bearing capabilities of metal gears.

It’s recommended to consult with gear manufacturers or mechanical engineers to determine the most appropriate gear material and design for a particular application, especially when high torque and load conditions are expected.

Can plastic gears be used in automotive applications?

Yes, plastic gears can be used in automotive applications. Here’s a detailed explanation:

Plastic gears have several advantages that make them suitable for certain automotive applications. They are lightweight, have good wear resistance, offer design flexibility, and can operate with low noise levels. However, it’s important to consider the specific requirements and limitations of automotive applications before using plastic gears.

1. Non-load Bearing Applications: Plastic gears are commonly used in non-load bearing applications within automotive systems. These include applications such as instrument clusters, HVAC systems, seat adjustments, and interior components. In these cases, the gears are subjected to relatively low loads and can effectively perform their functions while offering benefits such as weight reduction and cost efficiency.

2. Auxiliary Systems: Plastic gears can also be used in auxiliary systems of vehicles, such as windshield wipers, window regulators, and sunroof mechanisms. These systems typically operate at lower loads and speeds compared to primary powertrain components. Plastic gears can provide reliable performance in these applications while contributing to weight reduction and improved fuel efficiency.

3. Noise and Vibration: Plastic gears have inherent damping properties that can help reduce noise and vibration in automotive applications. This is particularly advantageous in areas where noise reduction is a priority, such as electric window mechanisms or HVAC systems. Plastic gears can contribute to a quieter and more comfortable driving experience.

4. Design Flexibility: Plastic gears offer design flexibility, allowing for complex shapes and customization to meet specific automotive requirements. They can be molded with precision to achieve intricate gear profiles and optimize gear performance. The flexibility in design can lead to improved efficiency, reduced weight, and space-saving advantages in automotive systems.

5. Material Selection: The selection of the appropriate plastic material is crucial for automotive applications. Certain plastic materials, such as engineering thermoplastics like POM (polyoxymethylene) or PA (polyamide), offer higher strength, rigidity, and wear resistance compared to standard plastics. These materials can withstand the demands of automotive environments, including temperature variations and exposure to chemicals or oils.

6. Load-Bearing Applications: While plastic gears are commonly used in non-load bearing or low-load applications within the automotive industry, they may have limitations in high-load or high-torque applications. Metal gears, such as steel or cast iron, are generally preferred for primary powertrain components such as transmissions and differential systems, where higher strength and durability are required to handle the significant loads and forces involved.

7. Environmental Considerations: Automotive applications can expose gears to various environmental factors such as temperature extremes, humidity, UV radiation, and exposure to chemicals or oils. The selected plastic material should have good resistance to these environmental conditions to ensure long-term durability and performance.

In summary, plastic gears can be successfully used in certain automotive applications, particularly in non-load bearing or low-load scenarios, as well as in auxiliary systems. They offer advantages such as weight reduction, design flexibility, and noise reduction. However, when considering the use of plastic gears in automotive applications, it’s important to carefully evaluate the specific requirements, loads, environmental conditions, and material selection to ensure optimal performance and durability.

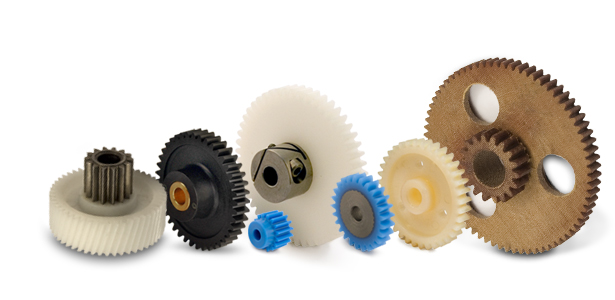

What are plastic gears and how are they used?

Plastic gears are gear components made from various types of polymers or plastic materials. They offer unique properties and advantages compared to traditional metal gears. Here’s a detailed explanation of plastic gears and their applications:

- Types of Plastic Materials: Plastic gears can be manufactured from different types of polymers, including thermoplastics such as acetal (polyoxymethylene – POM), nylon (polyamide – PA), polycarbonate (PC), and polyethylene (PE), as well as thermosetting plastics like phenolic resins. Each material has its own specific characteristics, such as strength, wear resistance, and temperature resistance, which make them suitable for different applications.

- Advantages of Plastic Gears: Plastic gears offer several advantages over metal gears, including:

- Lightweight: Plastic gears are lighter in weight compared to metal gears, which can be beneficial in applications where weight reduction is important.

- Low Noise and Vibration: Plastic gears can provide quieter operation due to their inherent damping properties that reduce noise and vibration levels.

- Corrosion Resistance: Certain plastic materials used in gear manufacturing exhibit excellent resistance to corrosion and chemicals, making them suitable for applications in corrosive environments.

- Self-Lubrication: Some plastic materials have self-lubricating properties, reducing the need for external lubrication and simplifying maintenance.

- Cost-Effective: Plastic gears can be more cost-effective compared to metal gears, especially in large-scale production, due to the lower material and manufacturing costs.

- Applications of Plastic Gears: Plastic gears find applications in various industries and systems, including:

- Automotive: Plastic gears are used in automotive systems such as windshield wipers, HVAC systems, seat adjusters, and electric power steering systems.

- Consumer Electronics: Plastic gears are commonly found in consumer electronics like printers, scanners, cameras, and home appliances.

- Medical Devices: Plastic gears are used in medical equipment and devices where weight reduction, low noise, and corrosion resistance are desired.

- Toy Manufacturing: Plastic gears are extensively used in the production of toys, including mechanical toys, hobby models, and educational kits.

- Office Equipment: Plastic gears are employed in office equipment like printers, copiers, and scanners, where quiet operation and cost-effectiveness are important.

- Industrial Machinery: Plastic gears can be utilized in various industrial machinery applications, such as conveyor systems, packaging equipment, and textile machinery.

It’s important to note that while plastic gears offer unique advantages, they also have limitations. They may not be suitable for applications requiring extremely high torque, high temperatures, or where precise positioning is critical. The selection of plastic gears should consider the specific requirements of the application and the mechanical properties of the chosen plastic material.

editor by CX 2023-10-18