Product Description

Product Description

Nylon Introduction:

Nylon,means Monomer Casting Nylon, is a kind of engineering plastics used in comprehensive industries, has been applied almost every industrial field.

The caprolactam monomer is first melted, and added catalyst, then poured it inside moulds at atmosphere pressure so as to shape in different castings, such as: rod, plate, tube. The molecule weight of MC Nylon can reach 70,05710,000/mol, three times than PA6/PA66. Its mechanical properties are much higher than other nylon materials, such as: PA6/PA66.

Property of PA6:

| Property | Item No. | Unit | Value | |

| Mechanical Properties | 1 | Density | g/cm3 | 1.13 |

| 2 | Water absorption(23ºC in air) | % | 1.8-2.0 | |

| 3 | Tensile strength | MPa | 86 | |

| 4 | Tensile strain at break | % | 28 | |

| 5 | Compressive stress(at 2%nominal strain) | MPa | 51 | |

| 6 | Charpy impact strength (unnotched) | KJ/m2 | No break | |

| 7 | Charpy impact strength (notched) | KJ/m2 | ≥5.7 | |

| 8 | Tensile modulus of elasticity | MPa | 3190 | |

| 9 | Ball indentation hardness | N/mm2 | 162 | |

| 10 | Rockwell hardness | – | M86 | |

Our Services

Wholesale of standard and nonstandard high-precision plastic gears, plastic pulleys and plastic gearboxes;

Designing, processing and manufacturing high-precision plastic gears and parts according to your drawings or samples;

Precision plastic injection molding and tooling.

Application & Industry

1. Textile Industry:

2. Chemical Industry:

3. Food Processing Industry:

4. Paper Industry:

5. Material Handling:

6. Farm Implement

7. Mining & Metals Processing Industries:

8. Transportation:

9. Consumer Products:

10. Waste Water Treatment

Why choose us?

1. We have our own factory, so we can supply you the factory price.

2. We are professional supplier, so we have our own technique personnel and sale team.

3. Delivery on time.

4. We have ISO9001:2008 certification and have professional personnel to 100% inspect the products,

so don’t worries about the quality.

5. Competitive price and nice service.

6. High quality products always can meet customers’ requirement.

7. Offer best service for our customers is our responsibility.

8. OEM and ODM service are available.

Quality guarantee

| chemical checking, NDE after rough machining, mechanical testing after heat treatment, final NDE, dimension inspected |

|

| Quality document | full Q.A document as per client request |

| Packing and shipping | standard export package(carton/wooden case/pallet) accept FOB,FAS,CNF,CIF door to door etc. or customer designated shipping agent. |

| Service | Drawing: we can translate your original drawing, offer best suggestion on design. Quality: we have full set quality control system to guarantee the best quality. Inspection: inspect in house, all our products must be checked 3 times before packing. |

| Inspection | in-house foundry third party inspection available upon requirement |

| Application: | Motor, Electric Cars, Machinery, Marine, Toy, Agricultural Machinery |

|---|---|

| Hardness: | Soft Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Nylon |

| Customization: |

Available

| Customized Request |

|---|

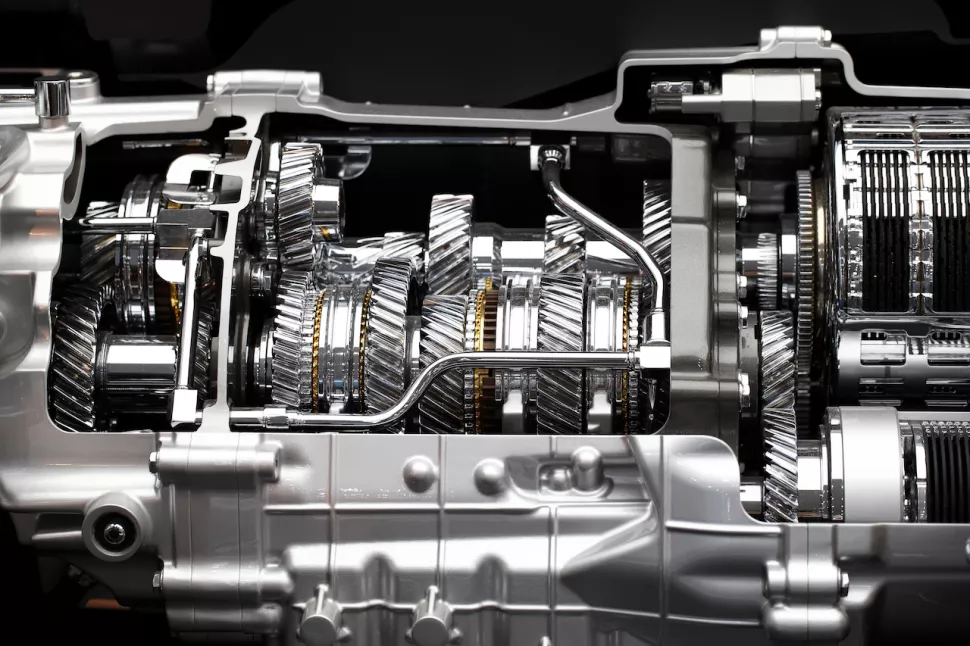

What are the signs of a worn-out or malfunctioning gear system in an automobile?

A worn-out or malfunctioning gear system in an automobile can exhibit several signs. Here’s a detailed explanation:

1. Difficulty Shifting Gears:

One of the most common signs of a gear system issue is difficulty shifting gears. You may experience resistance, grinding, or a clunking sound when trying to engage or disengage a gear. Gear shifts may feel rough or not engage smoothly, indicating potential problems with the clutch, synchro rings, or other transmission components.

2. Slipping Gears:

If you notice that the gear slips out of place while driving, causing sudden loss of power or RPM fluctuations, it could indicate a worn-out or faulty gear system. Slipping gears can be dangerous, as it can lead to a loss of control over the vehicle’s speed and acceleration.

3. Unusual Noises:

A malfunctioning gear system may produce unusual noises. You may hear grinding, rattling, whining, or humming sounds during gear shifts or while the vehicle is in motion. These noises can indicate issues with gear engagement, worn-out bearings, damaged gears, or other internal transmission problems.

4. Burning Smell:

A burning smell, similar to that of overheated or burnt clutch material, can indicate a problem with the gear system. This can occur due to excessive friction caused by a slipping clutch or other transmission issues. It’s important to address this promptly, as prolonged operation can cause further damage.

5. Gear Sluggishness:

If you notice a delay or sluggish response when shifting gears, it could be a sign of a gear system problem. The gears may take longer to engage, causing a delay in acceleration or difficulty maintaining speed. This can result from worn-out synchronizers, damaged gear teeth, or insufficient transmission fluid.

6. Gear Popping Out:

In some cases, a worn-out or faulty gear system can cause a gear to pop out of engagement unexpectedly. This can happen while driving or when changing gears, leading to an abrupt loss of power and potentially causing safety hazards on the road.

7. Transmission Fluid Leaks:

Leaking transmission fluid is another potential sign of a gear system problem. If you notice reddish fluid underneath the vehicle, it may indicate a transmission fluid leak. Insufficient fluid levels can affect gear lubrication and lead to gear system malfunctions.

8. Dashboard Warning Lights:

In modern vehicles, a malfunctioning gear system can trigger dashboard warning lights, such as the check engine light or transmission warning light. If you see any warning lights illuminated, it’s advisable to have the vehicle inspected by a qualified mechanic.

If you observe any of these signs, it’s crucial to have your vehicle inspected and diagnosed by a professional technician. They can accurately identify the cause of the gear system issue and recommend the necessary repairs or replacements to ensure the safe and proper operation of your vehicle.

What is the impact of gear selection on fuel efficiency in a car?

Gear selection in a car has a significant impact on fuel efficiency. Here’s a detailed explanation:

1. Optimal Engine Speed:

Choosing the right gear allows the engine to operate at its optimal speed or within its “power band.” Each engine has a range of RPM (revolutions per minute) where it delivers the best balance of power and fuel efficiency. By selecting the appropriate gear, the engine can stay within this range, maximizing fuel efficiency.

2. Engine Load:

Gear selection affects the load on the engine. Higher gears, such as fifth or sixth gear, provide a higher gear ratio, reducing the engine’s rotational speed for a given vehicle speed. This reduces the load on the engine and can improve fuel efficiency, especially during highway driving where maintaining a steady speed is common.

3. Avoiding Over-Revving:

Shifting to a higher gear at the right time helps prevent the engine from over-revving. Over-revving occurs when the engine operates at excessively high RPM, which can waste fuel and potentially cause engine damage. By upshifting in a timely manner, the engine can run at a more efficient RPM range, leading to better fuel economy.

4. Acceleration and Deceleration:

The choice of gear during acceleration and deceleration also affects fuel efficiency. During acceleration, shifting up to higher gears smoothly and at appropriate RPM levels promotes fuel efficiency. Similarly, when decelerating, downshifting to lower gears while utilizing engine braking can save fuel by reducing the need for excessive braking and maintaining better control over vehicle speed.

5. Driving Conditions:

The impact of gear selection on fuel efficiency can vary based on driving conditions. For example, in hilly or mountainous terrains, downshifting to lower gears on uphill climbs can provide the necessary power while avoiding excessive fuel consumption. In stop-and-go city traffic, selecting lower gears can aid in smoother acceleration from a standstill, reducing fuel waste.

6. Manual vs. Automatic Transmissions:

The impact of gear selection on fuel efficiency can differ between manual and automatic transmissions. Manual transmissions offer more control over gear selection, allowing drivers to optimize fuel efficiency by choosing the most suitable gear for a given situation. On the other hand, modern automatic transmissions are designed to optimize fuel efficiency by automatically selecting the appropriate gear based on driving conditions and engine load.

In summary, gear selection plays a crucial role in determining fuel efficiency in a car. Optimal gear selection helps keep the engine operating at its most efficient RPM range, reduces engine load, prevents over-revving, and promotes smoother acceleration and deceleration. By understanding the relationship between gear selection and fuel efficiency, drivers can adopt driving habits that maximize fuel economy and reduce fuel consumption.

How do different types of gears contribute to the operation of an automobile?

Various types of gears contribute to the operation of an automobile in different ways. Here’s a detailed explanation:

1. Spur Gears: Spur gears are the most common type of gears used in automobiles. They have straight teeth and are mounted on parallel shafts. Spur gears provide a simple and efficient way to transmit rotational power and motion between shafts. They are commonly used in transmissions to transfer power from the engine to the wheels at different gear ratios.

2. Helical Gears: Helical gears have angled teeth that are cut in a helix shape. This design allows for smoother and quieter operation compared to spur gears. In automobiles, helical gears are often used in the transmission system to provide smoother gear engagement and reduce noise and vibration during gear shifts.

3. Bevel Gears: Bevel gears have conical-shaped teeth and are used to transmit power between shafts that intersect at an angle. In automobiles, bevel gears are commonly found in the differential, which transfers power from the transmission to the wheels while allowing them to rotate at different speeds during turns. They are also used in the steering system to transfer power from the steering column to the wheels.

4. Worm Gears: Worm gears consist of a worm (a screw-like gear) and a worm wheel. They provide high gear reduction ratios and are often used in applications where high torque is required, such as power steering systems in automobiles. Worm gears offer self-locking properties, meaning they prevent the backdriving of the system, providing stability and safety.

5. Rack and Pinion Gears: Rack and pinion gears convert rotational motion into linear motion. They consist of a straight bar with teeth (rack) and a gear (pinion) that meshes with the rack. Rack and pinion gears are commonly used in the steering system of automobiles to convert the rotational motion of the steering wheel into linear motion, allowing the driver to control the direction of the vehicle.

6. Planetary Gears: Planetary gears, also known as epicyclic gears, consist of a sun gear, planet gears, and a ring gear. They offer high gear reduction ratios and compact designs. In automobiles, planetary gears are used in automatic transmissions to achieve different gear ratios and provide smooth gear changes without the need for manual shifting.

Each type of gear plays a specific role in the operation of an automobile, contributing to the transmission of power, speed control, torque multiplication, and directional control. The combination and arrangement of these gears in various automotive systems enable the vehicle to perform functions such as accelerating, decelerating, turning, and maintaining speed efficiently and safely.

editor by CX 2023-09-08