Product Description

OEM High-Accuracy Sintered Planetary Gear to Automobile Starters

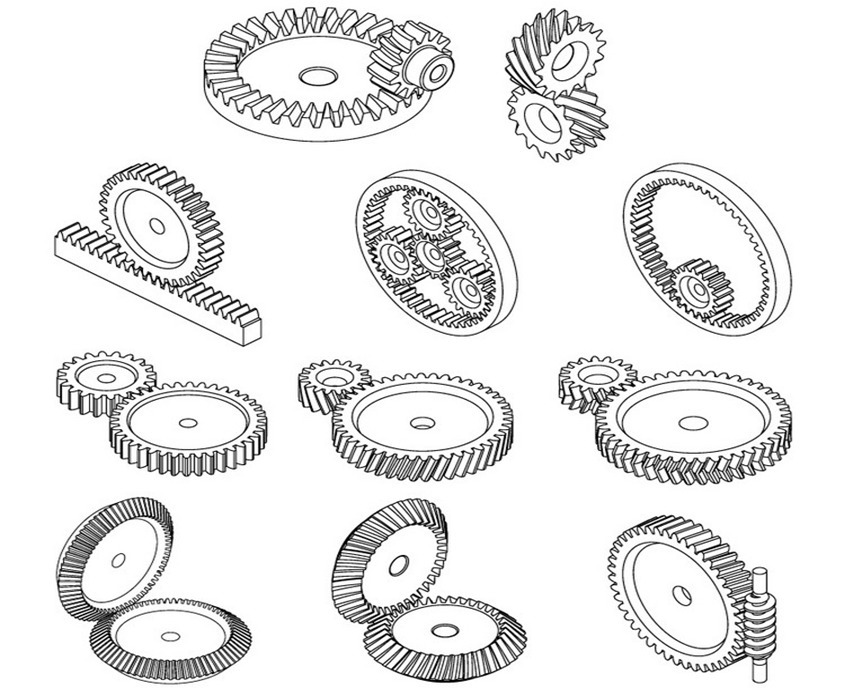

Gear transmission relies on the thrust between gear teeth to transmit motion and power, also known as meshing transmission. With this gradual meshing, helical gears operate much more smoothly and quietly than spur gears. Therefore, almost all automobile transmissions use helical gears.Since the teeth on the helical gear present a certain angle, the gears will be under a certain amount of stress when they mesh. Equipment using helical gears is equipped with bearings to withstand this pressure.

Product Description

Main Features:

Helical Gear

1. Produce strictly in accordance with ANSI or DIN standard dimension

2. Material: 45 Carbon Steel, /Stainless Steel

3. Bore: Finished bore

4. Module: 1~8

| Product name | Spur Gear & Helical Gear & Gear Shaft |

| Customized service | OEM, drawings or samples customize |

| Materials Available | Stainless Steel, Carbon Steel, S45C, SCM415, 20CrMoTi, 40Cr, Brass, SUS303/304, Bronze, Iron, Aluminum Alloy etc |

| Heat Treatment | Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding…… |

| Surface Treatment | Conditioning, Carburizing and Quenching,Tempering ,High frequency quenching, Tempering, Blackening, QPQ, Cr-plating, Zn-plating, Ni-plating, Electroplate, Passivation, Picking, Plolishing, Lon-plating, Chemical vapor deposition(CVD), Physical vapour deposition(PVD)… |

| BORE | Finished bore, Pilot Bore, Special request |

| Processing Method | Molding, Shaving, Hobbing, Drilling, Tapping, Reaming, Manual Chamfering, Grinding etc |

| Pressure Angle | 20 Degree |

| Hardness | 55- 60HRC |

| Size | Customer Drawings & ISO standard |

| Package | Wooden Case/Container and pallet, or made-to-order |

| Certificate | ISO9001:2008 |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

| Applications | Printing Equipment Industry, Laser Equipment Industry, Automated Assemblyline Industry, Woodening Industry, Packaging Equipment Industry, Logistics storage Machinery Industry, Robot Industry, Machine Tool Equipment Industry |

Company Profile

Packaging & Shipping

Packaging, Stock and Delivery:

| Packaging | Polyethylene bag or oil paper for each item; Pile on carton or as customer’s demand |

| Delivery of Samples | By DHL, Fedex, UPS, TNT, EMS |

| Lead time | 10-15 working days as usual, 30days in busy season, it will based on the detailed order quantity. |

FAQ

| Main Markets? | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order? | * You send us drawing or sample |

| * We carry through project assessment | |

| * We give you our design for your confirmation | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

If you are interested in our products, please tell us which materials, type, width, length u want.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Automation Equipment |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | Stainless Steel |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the signs of a worn-out or malfunctioning gear system in an automobile?

A worn-out or malfunctioning gear system in an automobile can exhibit several signs. Here’s a detailed explanation:

1. Difficulty Shifting Gears:

One of the most common signs of a gear system issue is difficulty shifting gears. You may experience resistance, grinding, or a clunking sound when trying to engage or disengage a gear. Gear shifts may feel rough or not engage smoothly, indicating potential problems with the clutch, synchro rings, or other transmission components.

2. Slipping Gears:

If you notice that the gear slips out of place while driving, causing sudden loss of power or RPM fluctuations, it could indicate a worn-out or faulty gear system. Slipping gears can be dangerous, as it can lead to a loss of control over the vehicle’s speed and acceleration.

3. Unusual Noises:

A malfunctioning gear system may produce unusual noises. You may hear grinding, rattling, whining, or humming sounds during gear shifts or while the vehicle is in motion. These noises can indicate issues with gear engagement, worn-out bearings, damaged gears, or other internal transmission problems.

4. Burning Smell:

A burning smell, similar to that of overheated or burnt clutch material, can indicate a problem with the gear system. This can occur due to excessive friction caused by a slipping clutch or other transmission issues. It’s important to address this promptly, as prolonged operation can cause further damage.

5. Gear Sluggishness:

If you notice a delay or sluggish response when shifting gears, it could be a sign of a gear system problem. The gears may take longer to engage, causing a delay in acceleration or difficulty maintaining speed. This can result from worn-out synchronizers, damaged gear teeth, or insufficient transmission fluid.

6. Gear Popping Out:

In some cases, a worn-out or faulty gear system can cause a gear to pop out of engagement unexpectedly. This can happen while driving or when changing gears, leading to an abrupt loss of power and potentially causing safety hazards on the road.

7. Transmission Fluid Leaks:

Leaking transmission fluid is another potential sign of a gear system problem. If you notice reddish fluid underneath the vehicle, it may indicate a transmission fluid leak. Insufficient fluid levels can affect gear lubrication and lead to gear system malfunctions.

8. Dashboard Warning Lights:

In modern vehicles, a malfunctioning gear system can trigger dashboard warning lights, such as the check engine light or transmission warning light. If you see any warning lights illuminated, it’s advisable to have the vehicle inspected by a qualified mechanic.

If you observe any of these signs, it’s crucial to have your vehicle inspected and diagnosed by a professional technician. They can accurately identify the cause of the gear system issue and recommend the necessary repairs or replacements to ensure the safe and proper operation of your vehicle.

What is the purpose of a differential gear in an automobile?

A differential gear in an automobile serves several important purposes. Here’s a detailed explanation:

1. Differential Action:

The primary purpose of a differential gear is to allow the wheels of an automobile to rotate at different speeds while receiving power from the engine. This is necessary when the vehicle is taking a turn, as the wheels on the outer side of the turn need to cover a greater distance and rotate faster than the wheels on the inner side.

2. Smooth Cornering:

By enabling the wheels to rotate at different speeds during a turn, the differential allows for smooth and controlled cornering. It prevents the tires from scrubbing and dragging along the road surface, which could lead to excessive tire wear and poor handling. Instead, the differential ensures that each wheel can rotate freely at the appropriate speed, maintaining traction and stability.

3. Power Distribution:

The differential also plays a crucial role in distributing power from the engine to the wheels. In a rear-wheel-drive vehicle, the differential is located on the rear axle, and it splits the engine torque between the two rear wheels. In a front-wheel-drive vehicle, the differential is integrated into the transaxle, transferring power to the front wheels.

4. Traction Enhancement:

Another function of the differential is to improve traction. When one wheel encounters a low-traction surface, such as ice or gravel, the differential allows power to be redirected to the wheel with better grip. This helps maintain traction and prevents wheel spin, allowing the vehicle to move forward more effectively in challenging driving conditions.

5. Compensation for Uneven Surfaces:

When driving on uneven surfaces, such as rough terrain or potholes, each wheel may experience different levels of vertical movement. The differential gear compensates for these variations in wheel movement, allowing the wheels to maintain contact with the ground and providing a smoother ride.

6. Reduction of Stress and Wear:

The differential helps reduce stress and wear on drivetrain components. By allowing the wheels to rotate at different speeds, it helps distribute the load evenly across the drivetrain, minimizing strain on components such as axles, driveshafts, and gears.

In summary, the differential gear in an automobile enables smooth cornering, power distribution, traction enhancement, compensation for uneven surfaces, and reduction of stress and wear on drivetrain components. It plays a vital role in ensuring optimal performance, handling, and stability of the vehicle.

What are the common types of automobile transmissions available?

There are several common types of automobile transmissions used in vehicles. Here’s a detailed explanation:

1. Manual Transmission: Manual transmissions, also known as “stick shift” or “standard” transmissions, require the driver to manually shift gears using a clutch pedal and gearshift lever. They typically have a set of forward gears, including first, second, third, fourth, and fifth (or sixth) gears, along with a reverse gear. Manual transmissions offer direct control over gear selection and are often preferred by enthusiasts for their engagement and control.

2. Automatic Transmission: Automatic transmissions use a torque converter and a complex system of planetary gears to automatically shift gears without driver intervention. They are the most common type of transmission in modern vehicles. Automatic transmissions provide smooth and convenient operation as they automatically select the appropriate gear ratio based on factors such as vehicle speed, engine load, and driver input. They typically offer “Drive” (D) mode for normal driving and may include additional modes like “Sport” (S) or “Economy” (E) for different driving preferences.

3. Continuously Variable Transmission (CVT): CVT is a type of automatic transmission that offers an infinite number of gear ratios within a specific range. Instead of using traditional gears, CVTs use a system of belts or chains and pulleys to provide seamless gear ratio changes. CVTs are known for their smoothness and fuel efficiency as they keep the engine operating at its most efficient RPM. They are commonly found in smaller vehicles and hybrid cars.

4. Dual-Clutch Transmission (DCT): DCT combines features of both manual and automatic transmissions. It uses two separate clutches for odd and even gears, allowing for quick and smooth gear shifts without interrupting power delivery. One clutch handles the current gear, while the other anticipates and prepares the next gear for engagement. DCTs provide fast and precise gear changes, making them popular in high-performance and sporty vehicles.

5. Automated Manual Transmission (AMT): AMT, also known as “Semi-Automatic Transmission” or “Clutchless Manual Transmission,” is essentially a manual transmission with automated clutch and gear shifting. Unlike traditional automatic transmissions, AMTs do not have a torque converter. Instead, they use actuators to control the clutch and gear selection based on the driver’s input or pre-programmed settings. AMTs are cost-effective alternatives to conventional automatic transmissions and are commonly found in entry-level or budget-friendly vehicles.

6. Sequential Manual Transmission (SMG) and Dual-Clutch Sequential Transmission: Sequential transmissions are commonly used in high-performance and racing vehicles. They allow for quick and precise sequential gear shifting without the need for a clutch pedal. SMGs use a single clutch, while dual-clutch sequential transmissions operate similarly to DCTs, with two clutches for improved performance and faster gear changes. Sequential transmissions provide rapid gear shifts, enhanced control, and are often controlled via paddle shifters mounted on the steering wheel.

These are some of the most common types of automobile transmissions available. Each type has its own advantages and characteristics, catering to different driving preferences, performance requirements, and fuel efficiency goals.

editor by CX 2023-09-22