Product Description

CNC Machined Components High Quality Starter Ring Gear for Automobile and Agriculture Industry

Production Capacities

| Service | High-precision CNC Machining (The precision is up to ±0.0005mm) |

| Sheet Metal Fabrication | |

| Stamping | |

| Die Casting | |

| Injection molding | |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Available Material | Steel, Brass, Zinc alloy , stainless steel, copper, aluminum alloy etc. |

| Surface Treatment | Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel,Plating, Chrome Plating, Dacromet, Enamel Coating etc. |

| OEM | Silkscreen, Engraving, Laser Printing, Cut-out making, Custom Packaging Box etc. |

| Application | All kinds of cars,machinery,home appliance,electronic products,electric appliance,stationery,computers,power switches,miniature switcher,architecture,commodity and A/V equipment,hardware and plastic molds,sports equipment and gifts,and more. |

| Manufacturing Type | Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, Grinding, Wie EDM, Stamping, Deep Drawing, CNC Punching, Laser Cutting, CNC Bending, Die Casting, Welding etc |

| Industries Served | Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical,Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS,STEP |

| QC | 100% Strict Inspection For Every Processing |

| One-stop Service | Custom Design, Fabrication, Assembly And Delivery |

| Packing | Packing according to your requirements |

Processing

Related Products

Customer Feedback

Company Profile

Our Advantages

Our Service

| Condition: | New |

|---|---|

| Certification: | CE, RoHS, ISO9001 |

| Standard: | DIN, GOST, GB |

| Customized: | Customized |

| Material: | Aluminum |

| Application: | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Samples: |

US$ 2.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the process of shifting gears smoothly in a manual car?

Shifting gears smoothly in a manual car is a skill that requires coordination and practice. Here’s a detailed explanation of the process:

1. Clutch Operation:

Before shifting gears, it’s essential to understand the operation of the clutch pedal. The clutch is used to temporarily disconnect the engine’s power from the transmission, allowing smooth gear engagement. To shift gears smoothly:

- Press the clutch pedal fully to disengage the clutch.

- Keep the clutch pedal depressed throughout the shifting process.

2. Throttle Control:

While shifting gears, it’s important to synchronize the engine speed (RPM) with the speed of the transmission. Here’s how to manage the throttle:

- Gradually release the accelerator pedal as you prepare to shift.

- Avoid abruptly lifting off the throttle, as it can cause a sudden drop in engine RPM.

3. Shifting Process:

Once the clutch is fully depressed, and the throttle is appropriately controlled, follow these steps to shift gears smoothly:

- Move the gear lever to the desired gear position while keeping the clutch pedal depressed.

- Avoid applying excessive force or rushing the gear lever movement.

- Wait for a brief moment after moving the gear lever to allow the gears to synchronize.

4. Releasing the Clutch:

After the gear lever is in the new position, smoothly release the clutch pedal while simultaneously modulating the throttle. Here’s how to do it:

- Gradually release the clutch pedal while applying gentle pressure on the accelerator pedal.

- Coordinate the release of the clutch with the increase in engine RPM.

- Avoid releasing the clutch too quickly or abruptly, as it can cause jerky gear engagement or stalling.

5. Practice and Smooth Transitions:

Smooth gear shifting requires practice and familiarity with the specific vehicle’s clutch and gearbox characteristics. Consider the following tips for achieving smooth transitions:

- Practice shifting gears in an open area with minimal traffic until you become comfortable.

- Develop a feel for the clutch engagement point, which is the position where the clutch starts to transmit power.

- Anticipate the need for gear changes by observing the engine RPM and road conditions.

- During upshifting, aim to shift gears when the engine RPM reaches a moderate level, typically between 2,000 and 3,000 RPM.

- During downshifting, match the engine RPM to the lower gear’s appropriate range to ensure smooth engagement.

Remember, mastering smooth gear shifting requires practice, coordination, and a good understanding of your vehicle’s clutch and gearbox. With time and experience, you’ll be able to shift gears seamlessly and enjoy a smoother driving experience.

Can you explain the concept of downshifting and upshifting in an automobile?

Downshifting and upshifting are fundamental concepts in operating a manual transmission vehicle. Here’s a detailed explanation:

1. Upshifting:

Upshifting refers to the process of shifting to a higher gear while driving. It involves moving the gear lever from a lower-numbered gear to a higher-numbered gear. The purpose of upshifting is to increase the vehicle’s speed while maintaining fuel efficiency and reducing engine RPM. Upshifting is typically done as the engine reaches its optimal RPM range or when the vehicle has gained sufficient speed in the current gear.

2. Downshifting:

Downshifting is the opposite of upshifting and involves shifting to a lower gear. It requires moving the gear lever from a higher-numbered gear to a lower-numbered gear. Downshifting is used to decrease the vehicle’s speed, increase engine RPM, and provide more power when needed, such as during overtaking, ascending steep hills, or slowing down. It allows the engine to operate at a higher RPM range, providing better acceleration and engine braking.

3. Rev Matching:

When downshifting, an important technique called “rev matching” is often employed. Rev matching involves synchronizing the engine speed (RPM) with the rotational speed of the transmission and wheels for a smooth gear engagement. By blipping the throttle or “heel-and-toe” technique, the driver matches the engine RPM to the desired speed in the lower gear before engaging the clutch and shifting down. Rev matching minimizes drivetrain shock, reduces wear on the clutch, and ensures a seamless transition between gears.

4. Benefits of Downshifting:

Downshifting offers several benefits, including:

- Improved acceleration: Downshifting to a lower gear provides more power and torque, allowing for quicker acceleration when needed.

- Engine braking: By downshifting and utilizing engine braking, drivers can slow down the vehicle without relying solely on the brakes. This can help maintain control, reduce brake wear, and prevent overheating of the braking system on long descents.

- Responsive driving: Downshifting allows drivers to have better control over the vehicle’s speed and responsiveness, especially in situations where immediate power is required.

5. Automatic Transmissions:

While the concept of upshifting and downshifting primarily applies to manual transmissions, modern automatic transmissions also incorporate similar principles. Automatic transmissions automatically shift gears based on factors such as vehicle speed, engine load, and driver input. They can upshift and downshift to optimize fuel efficiency, provide smooth acceleration, and deliver appropriate power based on driving conditions.

In summary, upshifting involves shifting to a higher gear to increase speed and maintain fuel efficiency, while downshifting involves shifting to a lower gear to decrease speed, increase power, and utilize engine braking. Downshifting offers benefits such as improved acceleration, engine braking, and responsive driving. Understanding the concept of shifting gears is essential for manual transmission operation and can enhance the driving experience and control over the vehicle.

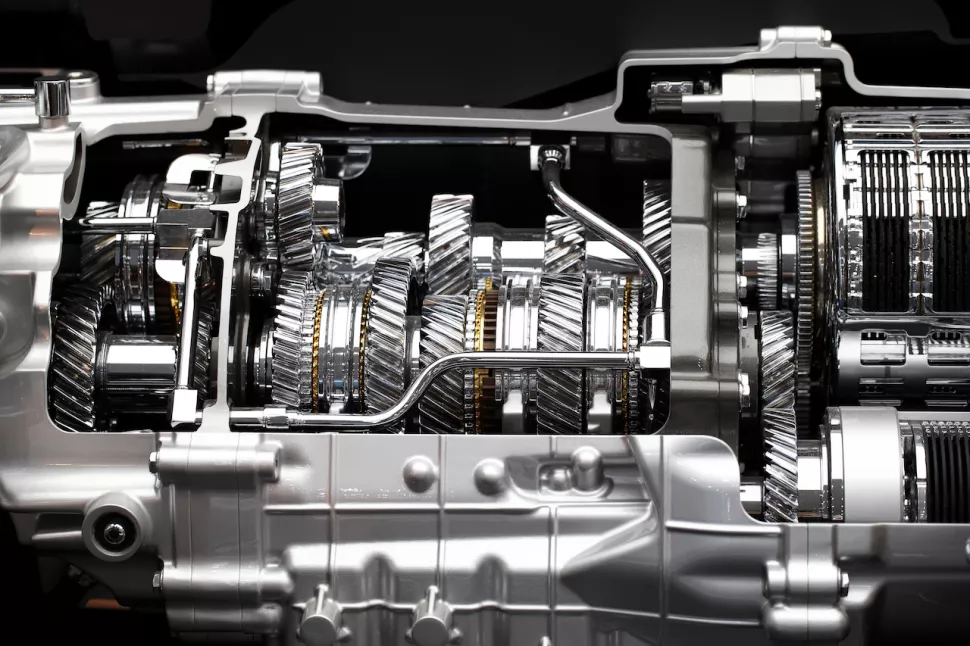

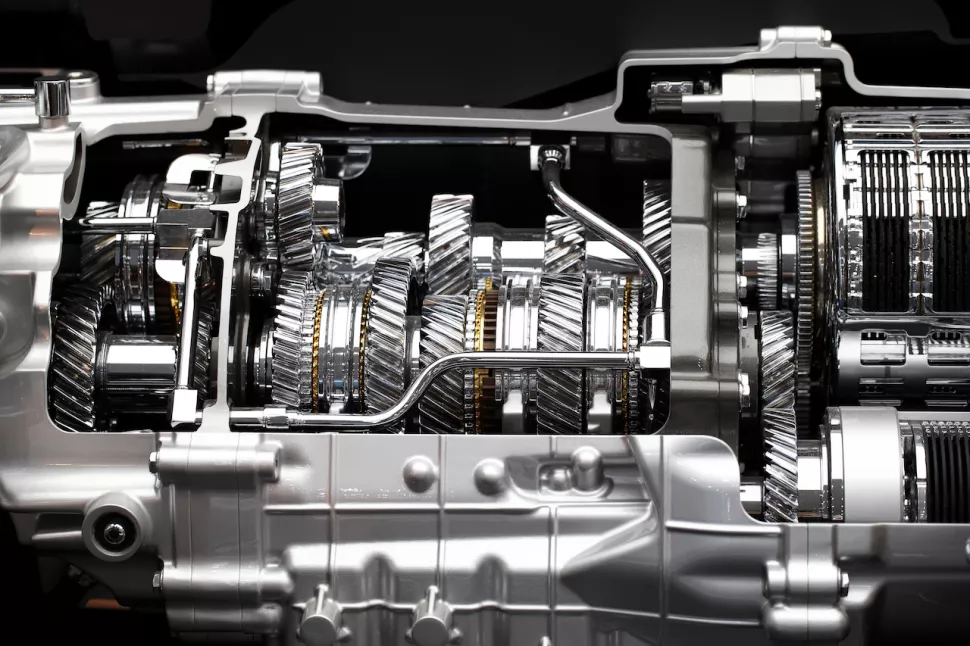

How do different types of gears contribute to the operation of an automobile?

Various types of gears contribute to the operation of an automobile in different ways. Here’s a detailed explanation:

1. Spur Gears: Spur gears are the most common type of gears used in automobiles. They have straight teeth and are mounted on parallel shafts. Spur gears provide a simple and efficient way to transmit rotational power and motion between shafts. They are commonly used in transmissions to transfer power from the engine to the wheels at different gear ratios.

2. Helical Gears: Helical gears have angled teeth that are cut in a helix shape. This design allows for smoother and quieter operation compared to spur gears. In automobiles, helical gears are often used in the transmission system to provide smoother gear engagement and reduce noise and vibration during gear shifts.

3. Bevel Gears: Bevel gears have conical-shaped teeth and are used to transmit power between shafts that intersect at an angle. In automobiles, bevel gears are commonly found in the differential, which transfers power from the transmission to the wheels while allowing them to rotate at different speeds during turns. They are also used in the steering system to transfer power from the steering column to the wheels.

4. Worm Gears: Worm gears consist of a worm (a screw-like gear) and a worm wheel. They provide high gear reduction ratios and are often used in applications where high torque is required, such as power steering systems in automobiles. Worm gears offer self-locking properties, meaning they prevent the backdriving of the system, providing stability and safety.

5. Rack and Pinion Gears: Rack and pinion gears convert rotational motion into linear motion. They consist of a straight bar with teeth (rack) and a gear (pinion) that meshes with the rack. Rack and pinion gears are commonly used in the steering system of automobiles to convert the rotational motion of the steering wheel into linear motion, allowing the driver to control the direction of the vehicle.

6. Planetary Gears: Planetary gears, also known as epicyclic gears, consist of a sun gear, planet gears, and a ring gear. They offer high gear reduction ratios and compact designs. In automobiles, planetary gears are used in automatic transmissions to achieve different gear ratios and provide smooth gear changes without the need for manual shifting.

Each type of gear plays a specific role in the operation of an automobile, contributing to the transmission of power, speed control, torque multiplication, and directional control. The combination and arrangement of these gears in various automotive systems enable the vehicle to perform functions such as accelerating, decelerating, turning, and maintaining speed efficiently and safely.

editor by CX 2023-12-07